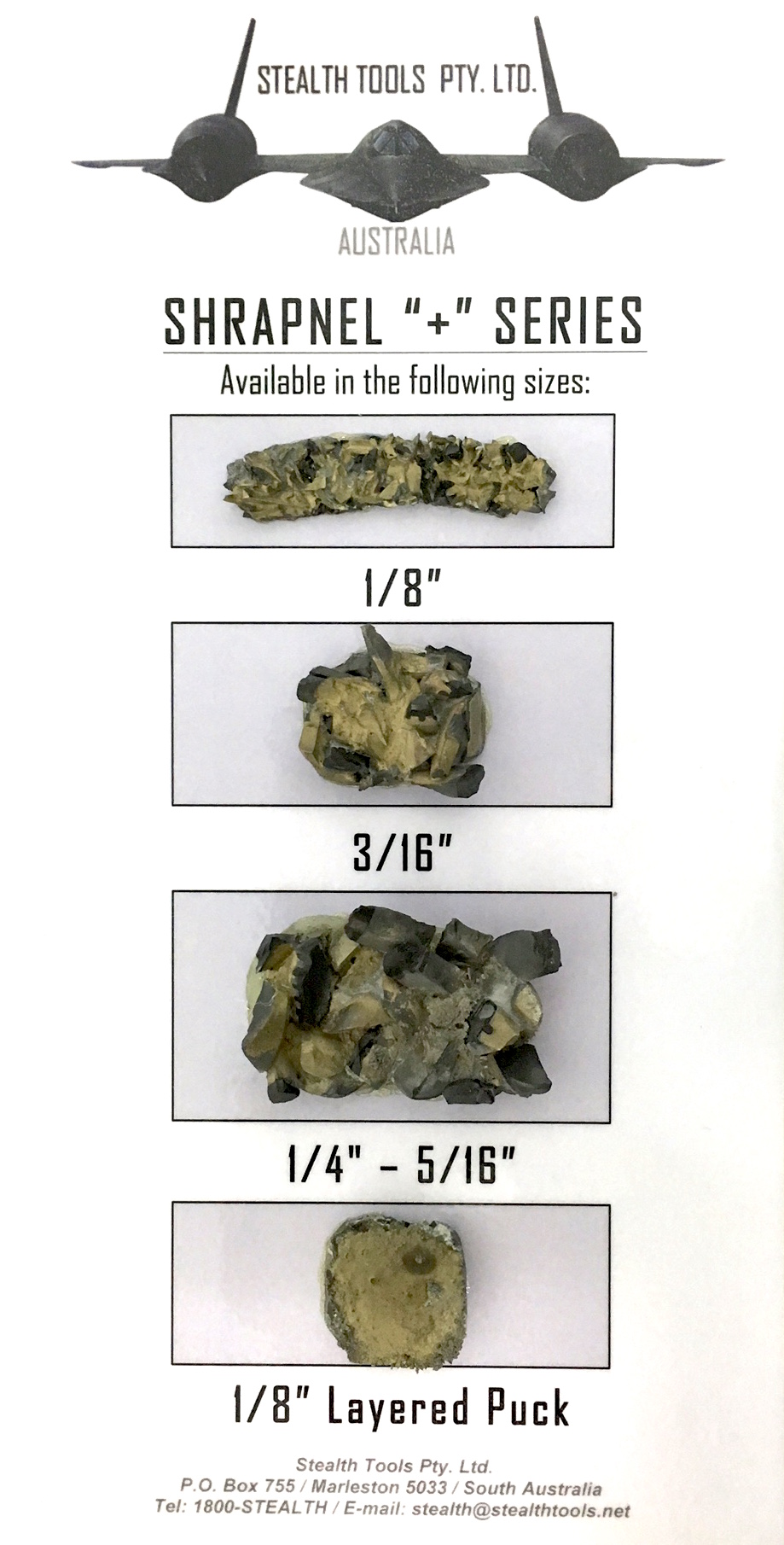

New Stealth "SHRAPNEL" Series

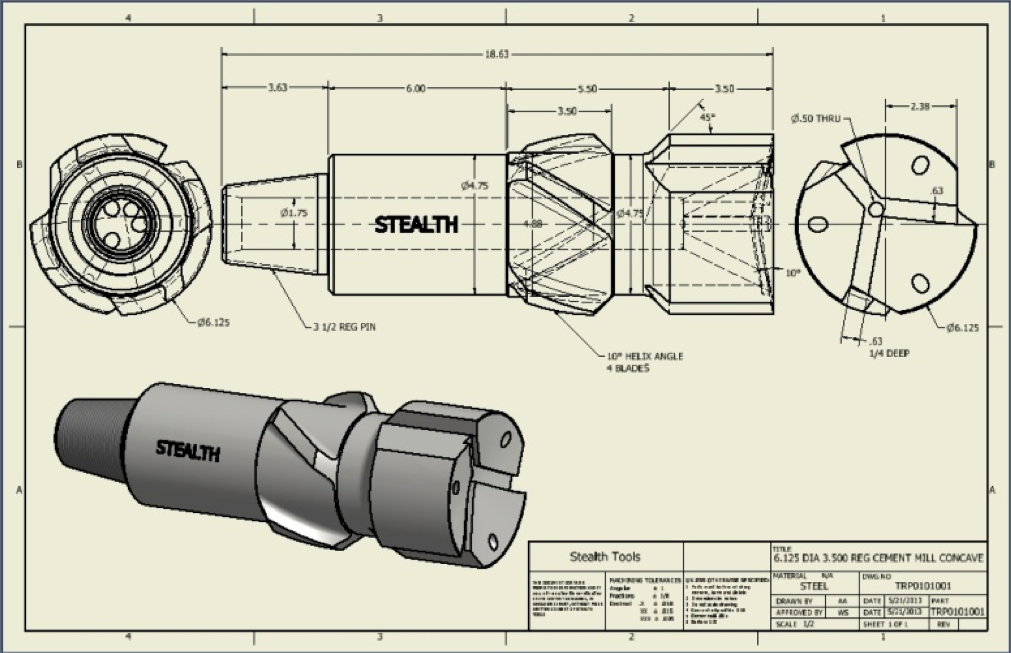

Stealth Tools is proud to unleash our proprietary “Shrapnel” coated Milling, Drilling and Stabilizing products. Undergoing current trials in situations where no other option has succeeded thus far, our new Stealth SCM+ (Stealth Concave Mill + Shrapnel) is providing a new and exciting opportunity to mill/drill a diverse range of downhole obstructions to get the client to where they need to be.

The SCM+, and all + series “Shrapnel” tools, utilise our proprietary “Stealth Shrapnel” technology, which consists of broken PDC cutters from our PDC refurbishment service, reclaimed and crushed to be applied to the cutting surface with our hard wearing braze. To help with cuttings removal, the TFA and fluid paths have been made as large as possible for a more efficient flow, as well as to optimise the fluid movement for effective cutting removal.

This revolutionary new way of reusing broken diamond to create an extremely durable, aggressive and versatile cutting surface, has also been applied to other BHA components such as spiral string stabilisers, where it has been effective in reaming small ledges or obstructions behind the bit, helping reduce the amount of tripping to ream, thus keeping the hole diameters and well integrity as high as possible.

Stealth also provides full customisation for your operational requirements, with customised designs from multiple segmented concave, to watermelon, stepped or tapered designs available. With the ability to manufacture any and all sizes, with custom connections to suit your needs, the “Shrapnel” series mills, drills and stabilizers are also completely refurbish-able at out Adelaide facility, adding longevity and economy to your operations.

For further information, or to enquire about how the “Shrapnel” series of options could help your company overcome (or get through) any obstacle, call our Australian toll free number on 1800-STEALTH, or contact us at: stealth@stealthtools.net